CAMSHAFT (for Bank 2) > INSPECTION |

| 1. INSPECT CAMSHAFT |

|

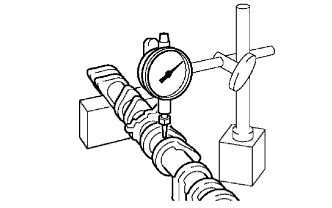

Inspect the camshaft for runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

|

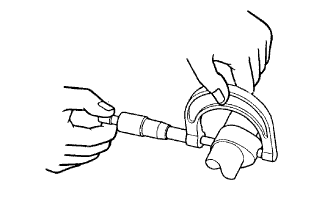

Inspect the cam lobes.

Using a micrometer, measure the cam lobe height.

| Camshaft | Cam lobe height |

| Intake | 44.168 to 44.268 mm (1.7389 to 1.7428 in.) |

| Exhaust | 44.580 to 44.680 mm (1.7551 to 1.7591 in.) |

| Camshaft | Cam lobe height |

| Intake | 44.018 mm (1.7330 in.) |

| Exhaust | 44.430 mm (1.7492 in.) |

|

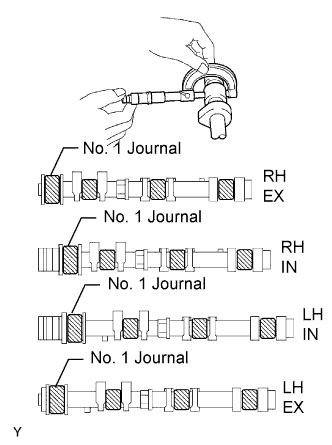

Inspect the camshaft journals.

Using a micrometer, measure the journal diameter.

| Journal | Diameter |

| No. 1 journal | 35.971 to 35.985 mm (1.4162 to 1.4167 in.) |

| Other journal | 22.959 to 22.975 mm (0.9039 to 0.9045 in.) |

| 2. INSPECT CAMSHAFT TIMING GEAR |

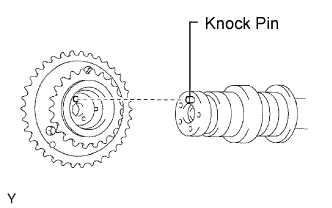

Fix the intake camshaft with a vise.

|

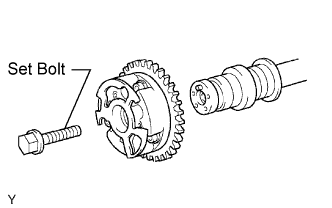

Align the knock pin hole in the camshaft timing gear assembly with the knock pin of the camshaft, and install the camshaft timing gear assembly with the bolt.

Confirm the camshaft timing gear assembly is locked.

|

Release the lock pin.

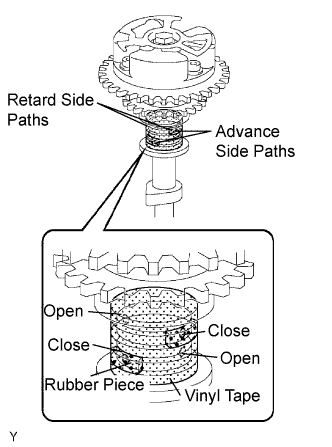

Cover 4 oil paths of cam journal with vinyl tape as shown in the illustration.

Break through the tapes of the advance side path and the retard side path on the opposite side of the groove.

|

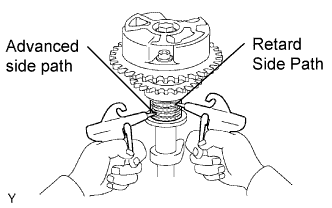

Put air pressure into 2 broken paths (the advance side path and the retard side path) with about 200 kPa (2.0 kgf/cm2, 28 psi).

|

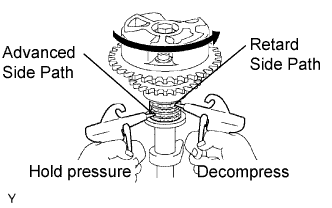

Confirm if the camshaft timing gear assembly rotates in the timing advance direction when weakening the air pressure of the timing retard path.

When the camshaft timing gear comes to the most advanced position, take out the air pressure of the timing retard side path, and then take out that of timing advance side path.

Check the smooth revolution.

Except the position where the lock pin meets at the most retard angle, let the camshaft timing gear assembly turn back and forth and check the movable range and that there is no disturbance.

Check the lock in the most retarded position.

Confirm that the camshaft timing gear assembly is locked at the most retarded position.

|

Remove the set bolt and camshaft timing gear assembly.