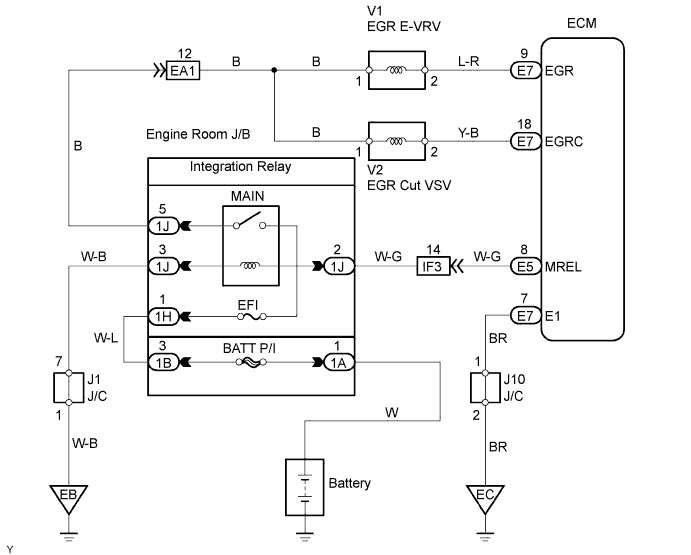

ECD SYSTEM > EGR Control Circuit |

| 1.CHECK CONNECTION OF VACUUM HOSE |

Check the connection of vacuum hose.

|

| ||||

| OK | |

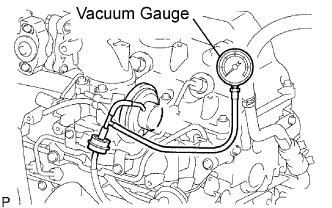

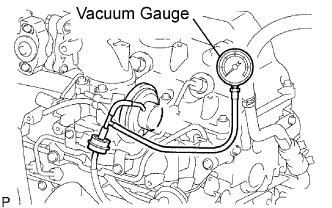

| 2.CHECK VACUUM |

|

Using a 3-way connector, connect a vacuum gauge to the vacuum hose between the EGR E-VRV and EGR valve.

Warm up the engine to above 80°C (176°F).

Chck the vacuum at 1,500rpm.

| Vacuum | Proceed to |

| 0 kPa (0 mmHg, 0 in.Hg) | A |

| 0 kPa (0 mmHg, 0 in.Hg) to 28 kPa (210 mmHg, 8.3 in.Hg) | B |

| Above 28 kPa (210 mmHg, 8.3 in.Hg) | C |

|

| ||||

|

| ||||

| B | |

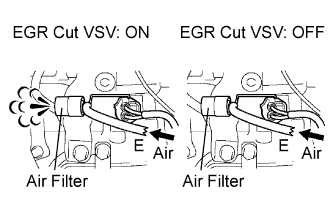

| 3.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (EGR CUT VACUUM SWITCHING VALVE) |

|

Disconnect the vacuum hose from the VSV.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester II ON.

Enter the following menus: Powertrain / Engine / Active Test / Activate the VSV for EGR Cut.

Check the operation.

|

| ||||

| NG | |

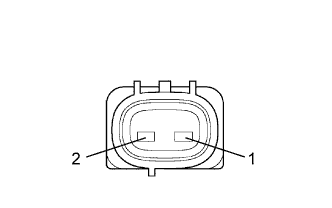

| 4.INSPECT EGR CUT VACUUM SWITCHING VALVE |

|

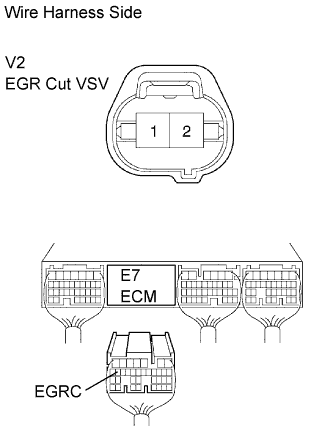

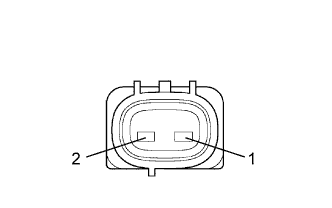

Disconnect the V2 VSV connector.

Measure the resistance of the VSV.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68°F) | 37 to 44 Ω |

|

| ||||

| OK | |

| 5.CHECK WIRE HARNESS (EGR CUT VACUUM SWITCHING VALVE - ECM) |

|

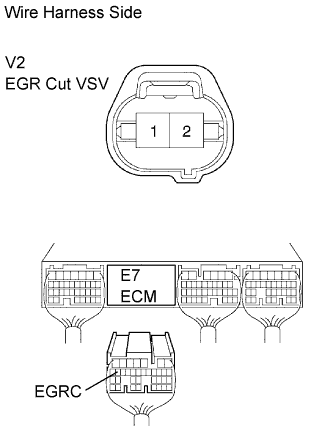

Disconnect the V2 VSV connector.

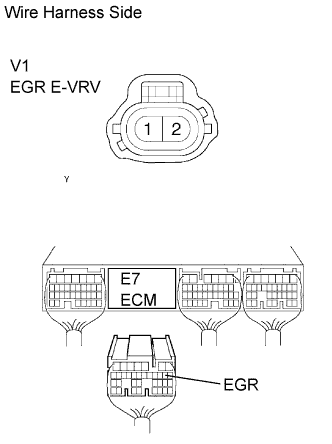

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E7-18 (EGRC) - V2-2 | Below 1 Ω |

| E7-18 (EGRC) or V2-2 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 6.CHECK WIRE HARNESS (EGR CUT VACUUM SWITCHING VALVE - MAIN RELAY) |

|

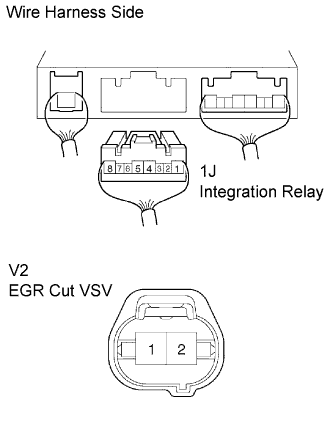

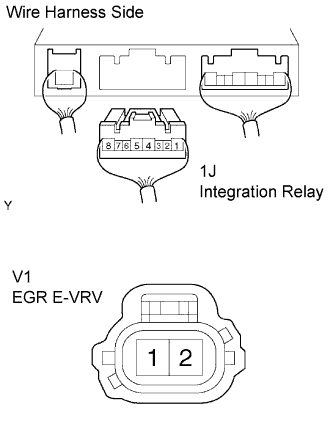

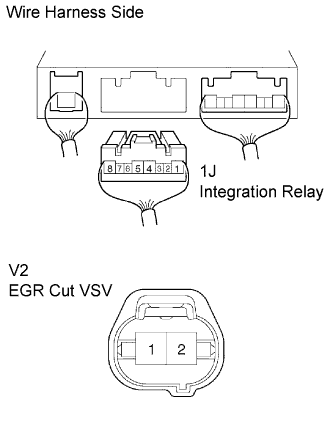

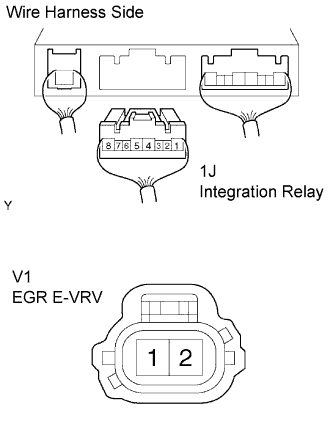

Remove the integration relay from the engine room J/B (Click here).

Disconnect the 1J integration relay connector.

Disconnect the V2 VSV connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| 1J-5 - V2-1 | Below 1 Ω |

| 1J-5 or V2-1 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 7.CHECK ECM (EGR VOLTAGE) |

|

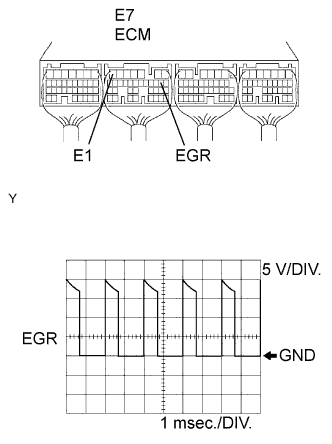

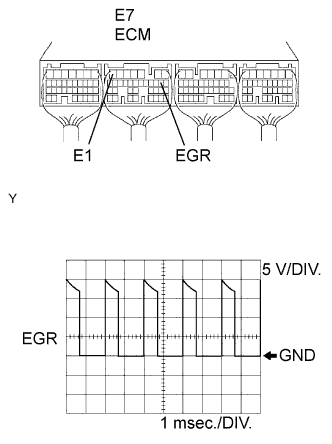

Disconnect the V1 E-VRV connector.

During idling, check the waveform of the ECM connector.

| Tester Connection | Specified Condition |

| E7-9 (EGR) - E7-7 (E1) | Correct waveform is as shown |

| Tool Setting | Condition |

| 5 V/DIV., 1 msec./DIV. | Idling with warm engine |

|

| ||||

| OK | |

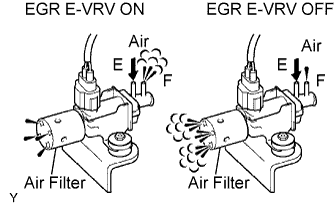

| 8.CHECK OPERATION OF EGR ELECTRIC VACUUM REGULATING VALVE |

|

Disconnect the vacuum hoses from the E-VRV.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Active Test / Control the EGR System.

Check the operation.

|

| ||||

| NG | |

| 9.INSPECT EGR ELECTRIC VACUUM REGULATING VALVE (RESISTANCE) |

|

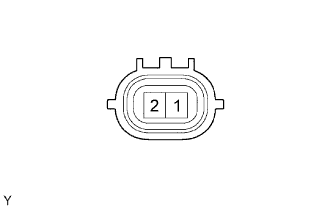

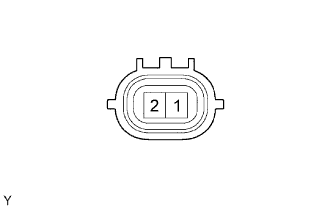

Disconnect the V1 E-VRV connector.

Measure the resistance of the E-VRV.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68°F) | 11 to 13 Ω |

|

| ||||

| OK | |

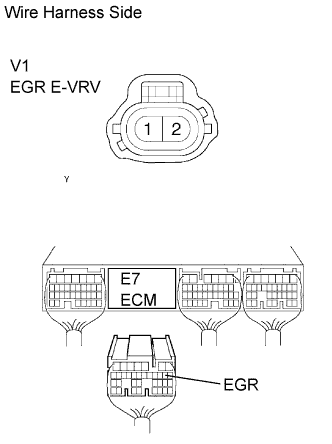

| 10.CHECK WIRE HARNESS (EGR ELECTRIC VACUUM REGULATING VALVE - ECM) |

|

Disconnect the V1 E-VRV connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E7-9 (EGR) - V1-2 | Below 1 Ω |

| E7-9 (EGR) or V1-2 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 11.CHECK WIRE HARNESS (EGR ELECTRIC VACUUM REGULATING VALVE - MAIN RELAY) |

|

Remove the integration relay from the engine room J/B (see page ).

Disconnect the 1J integration relay connector.

Disconnect the V1 E-VRV connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| 1J-5 - V1-1 | Below 1 Ω |

| 1J-5 or V1-1 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 12.INSPECT EGR VALVE ASSEMBLY |

|

| ||||

| OK | ||

| ||

| 1.CHECK CONNECTION OF VACUUM HOSE |

Check the connection of vacuum hose.

|

| ||||

| OK | |

| 2.CHECK VACUUM |

|

Using a 3-way connector, connect a vacuum gauge to the vacuum hose between the EGR E-VRV and EGR valve.

Warm up the engine to above 80°C (176°F).

Chck the vacuum at 1,500rpm.

| Vacuum | Proceed to |

| 0 kPa (0 mmHg, 0 in.Hg) | A |

| 0 kPa (0 mmHg, 0 in.Hg) to 28 kPa (210 mmHg, 8.3 in.Hg) | B |

| Above 28 kPa (210 mmHg, 8.3 in.Hg) | C |

|

| ||||

|

| ||||

| B | |

| 3.INSPECT EGR CUT VACUUM SWITCHING VALVE |

|

Disconnect the V2 VSV connector.

Measure the resistance of the VSV.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68°F) | 37 to 44 Ω |

|

| ||||

| OK | |

| 4.INSPECT EGR CUT VACUUM SWITCHING VALVE (OPERATION) |

|

| ||||

| OK | |

| 5.CHECK WIRE HARNESS (EGR CUT VACUUM SWITCHING VALVE - ECM) |

|

Disconnect the V2 VSV connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E7-18 (EGRC) - V2-2 | Below 1 Ω |

| E7-18 (EGRC) or V2-2 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 6.CHECK WIRE HARNESS (EGR CUT VACUUM SWITCHING VALVE - MAIN RELAY) |

|

Remove the integration relay from the engine room J/B (Click here).

Disconnect the 1J integration relay connector.

Disconnect the V2 VSV connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| 1J-5 - V2-1 | Below 1 Ω |

| 1J-5 or V2-1 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 7.CHECK ECM (EGR VOLTAGE) |

|

Disconnect the V1 E-VRV connector.

During idling, check the waveform of the ECM connector.

| Tester Connection | Specified Condition |

| E7-9 (EGR) - E7-7 (E1) | Correct waveform is as shown |

| Tool Setting | Condition |

| 5 V/DIV., 1 msec./DIV. | Idling with warm engine |

|

| ||||

| OK | |

| 8.INSPECT EGR ELECTRIC VACUUM REGULATING VALVE (RESISTANCE) |

|

Disconnect the V1 E-VRV connector.

Measure the resistance of the E-VRV.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68°F) | 11 to 13 Ω |

|

| ||||

| OK | |

| 9.INSPECT EGR ELECTRIC VACUUM REGULATING VALVE (OPERATION) |

|

| ||||

| OK | |

| 10.CHECK WIRE HARNESS (EGR ELECTRIC VACUUM REGULATING VALVE - ECM) |

|

Disconnect the V1 E-VRV connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E7-9 (EGR) - V1-2 | Below 1 Ω |

| E7-9 (EGR) or V1-2 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 11.CHECK WIRE HARNESS (EGR ELECTRIC VACUUM REGULATING VALVE - MAIN RELAY) |

|

Remove the integration relay from the engine room J/B (Click here).

Disconnect the 1J integration relay connector.

Disconnect the V1 E-VRV connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| 1J-5 - V1-1 | Below 1 Ω |

| 1J-5 or V1-1 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 12.INSPECT EGR VALVE ASSEMBLY |

|

| ||||

| OK | ||

| ||